Doors are open for TL 361, a new eight-story apartment infill for San Francisco’s Tenderloin neighborhood. 361 Turk Street has created over a hundred new micro homes using efficient construction methods and technology throughout the building to reduce the carbon footprint and overall costs. Forge Development Partners and Bridge Investment Group are joint venture partners.

361 Turk Street exterior, image by author

361 Turk Street view from top-floor balcony, image by author

Earlier this month, YIMBY was given a tour of the premises along with Richard Hannum, a founding partner at Forge Development Partners. Hannum emphasizes that the long and the short of it is that sustainability is not only a good idea, it’s also good for investment, saving expenses, and reducing rates.

Forge and Bridge have developed a similar project at 145 Leavenworth Street. Construction on TL 145 is expected to finish in late November or early December. Both projects have replaced former surface parking lots. Combined, both projects will open 240 new homes in the neighborhood.

145 Leavenworth Street as seen during visit, image by author

361 Turk Street water heating system, image by author

Both TL 361 and TL 145 use the Pueblo Structural System created by San Francisco architect Jorge Dequesada AIA. The structure was planned by Gensler and Olson Steel. As a result, the structure is approximately 30% lighter than a steel structure would otherwise be, using around 90-95% recycled steel, and limited use of concrete. The steel beams are also visible in the corridors as a visual reminder of the Pueblo system. The method enables quick construction and a reduced carbon footprint compared with traditional multifamily projects.

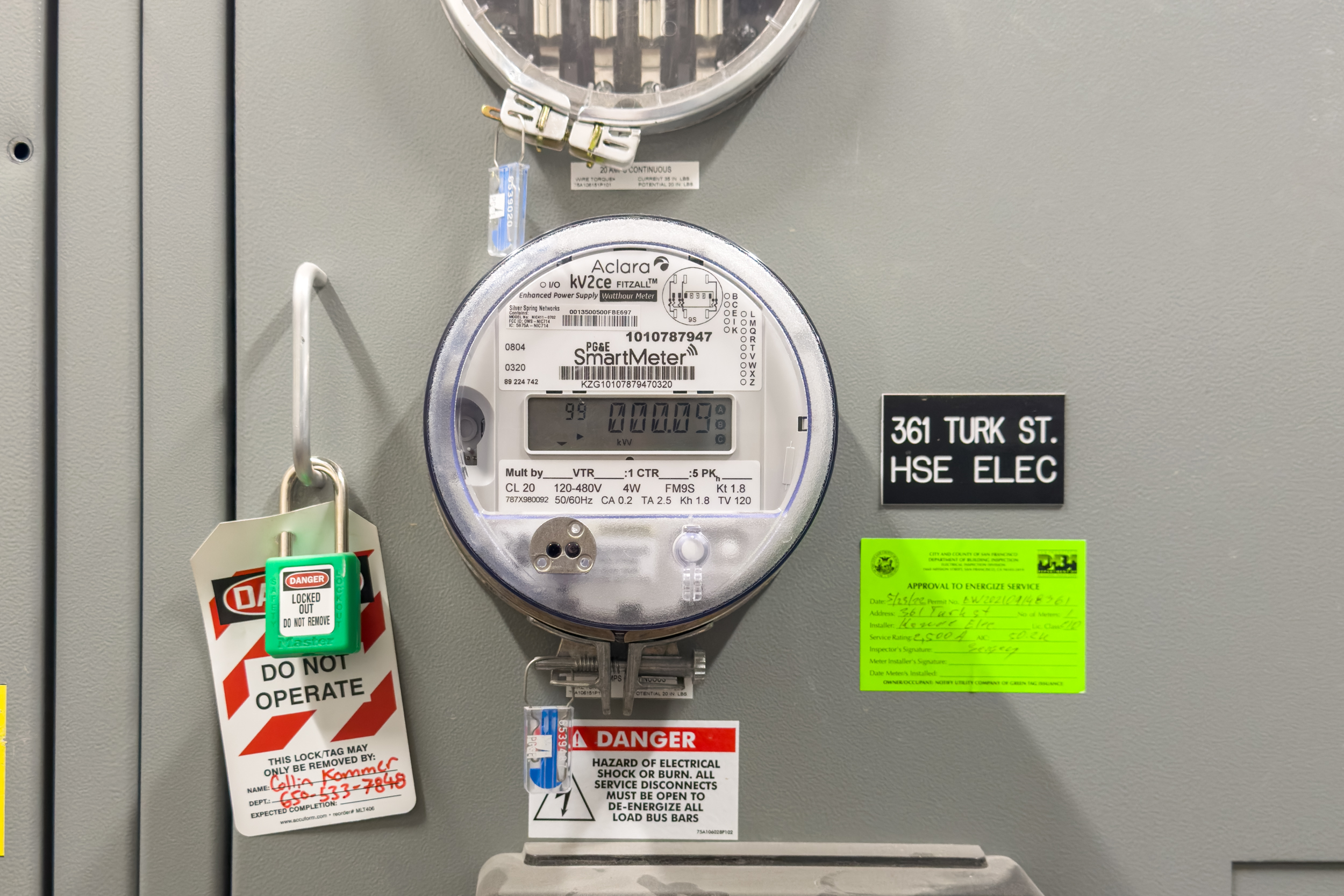

The team has also achieved savings of around $50,000 per unit by using a single meter for the whole building. TL 361 is the first multi-family project in California to obtain permits to do so by PG&E in thirty years. Even with a single meter for the whole site, each resident can control the temperature of their individual unit thermostat.

With the reduced energy needs by nearly a third, the use of solar energy, and a novel water heating system on the roof, Forge is able to lower energy costs as compared with a traditional structure.

The single meter overseeing the power across 361 Turk Street, image by author

Gensler is responsible for the design, which is expected to achieve at least LEED Gold certification. Writing with YIMBY, project architect Doug Zucker provided further context for how the studio approached the plans for TL 361.

361 Turk is an example of rethinking the current paradigm of building housing, which currently doesn’t work in San Francisco. With 361 Turk, in order to make housing more affordable, we had to start from scratch and look at all of the systems that make up construction today. It is completely rethought from the structural system to the water and electrical systems. The project approach was to put less square footage into the units and more into all of the amenities and public spaces, which are extensive and compete with a luxury building. The goal was to create community, which is so often lacking in rental apartment buildings.”

As part of the development arts contribution for the neighborhood, Forge has used two designs for the facades designed by SOTA high school students. For TL 361, Hannum shared that the reflective metal-carved building is an expression of the meter from “So What,” the Miles Davis song recorded in the Tenderloin’s Blackhawk nightclub. The new facades contribute to the National Historic District’s cultural assets.

The two eight-story structures yield a combined 98,060 square feet. The base of TL 361 will feature 3,000 square feet of retail with outdoor seating, likely to become a food services space. Parking will be included for bicycles, a decision that will promote the neighborhood’s traffic conditions and public transit.

361 Turk Street murphy bed, rendering by Gensler

361 Turk Street apartment murphy bed in set unit, image by author

Each unit ranges from 230 to 280 square feet, with an in-unit convection oven, induction plates, and a bathroom. Apartments facing the street will have a private open-air balcony. Residents are offered a murphy bed that converts into a couch to maximize space. The team also found an in-unit fridge with a freezer space that operates at 40 decibels.

The thermostat includes an air quality meter. Residents will also benefit from a HEPA-filtered air system designed to help reduce the effects of smoke inside. The entire building is designed around the Internet of Things, i.e., IoT, connecting doors, in-unit climate control, amenities, and services through a phone app. The site is also connected with fiber optic Wi-Fi so residents can access a private connection to Wi-Fi anywhere.

The IoT connects residents to building ownership, event services programming, and reservations for the fitness center and amenity spaces. Various double-height amenity spaces are included on alternating floors to offer residents shared workspaces, gym equipment, and a laundry room with natural light. An inner-block courtyard includes a fire pit, while the basement amenity room, named the Del Seymour Room, features an equipped kitchen that can double for events and classes with residents. The rooftop deck includes a dog run, seating, and barbeque grills.

361 Turk Street apartment interior, rendering by Gensler

361 Turk Street Del Seymour Room kitchen, image by author

The Del Seymour Room is dedicated to the active community organizer at Code Tenderloin and Tenderloin Walking Tours. The space will be open for the group and other local organizations to reserve.

Forge and Bridge are partners through a joint venture for TL145 and Tl 361, with Bridge using their $1.74 billion workforce Housing Fund. The development has been financed by Forward Commitment from Freddie Mac, East West Bank, and Washington Federal. Forge has also used CrowdStreet, a leading Financial Tech platform, to raise initial equity from accredited investors.

361 Turk Street amenity room, image by author

The project was able to privately impose an income restriction for approximately 51% of all units with assistance from the Forward Commitment fund. Inside TL 361, 120 units will be restricted for households earning as much as 90% of the Area Median Income. Of that, 31 units will be for households earning around $32,000 per year, controlled by the Mayor’s Office of Housing and Community Development. Forge will offer the remaining units at market rate for a cost reachable for households earning around $82,000 per year.

While the project had hoped to become a model for future affordable housing infills in San Francisco, this is unlikely as the Board of Supervisors has passed a law to prevent new ‘group housing’ developments, especially for Chinatown and the Tenderloin. However, Forge is working on a similar project in San Diego and has sights across the Bay Area.

Future residents will be in a dense urban neighborhood with a plethora of shops and businesses, public transit, and job opportunities in the Civic Center, Financial District, and SoMa.

Forge hopes to fill both projects within a year.

Subscribe to YIMBY’s daily e-mail

Follow YIMBYgram for real-time photo updates

Like YIMBY on Facebook

Follow YIMBY’s Twitter for the latest in YIMBYnews

Very New Yorky- I like it! More low income housing that doesn’t sacrifice build quality and longevity is much needed in this area. Just because you can’t afford a larger home, doesn’t mean you need to deal with basic necessities malfunctioning like plumbing, heating, water & pest intrusion.

Saving $50,000 per unit because they only used one meter! Isn’t that a little ridiculous, to say the least? That’s a lot for just putting a meter on after doing all the wiring that they have to do anyway.